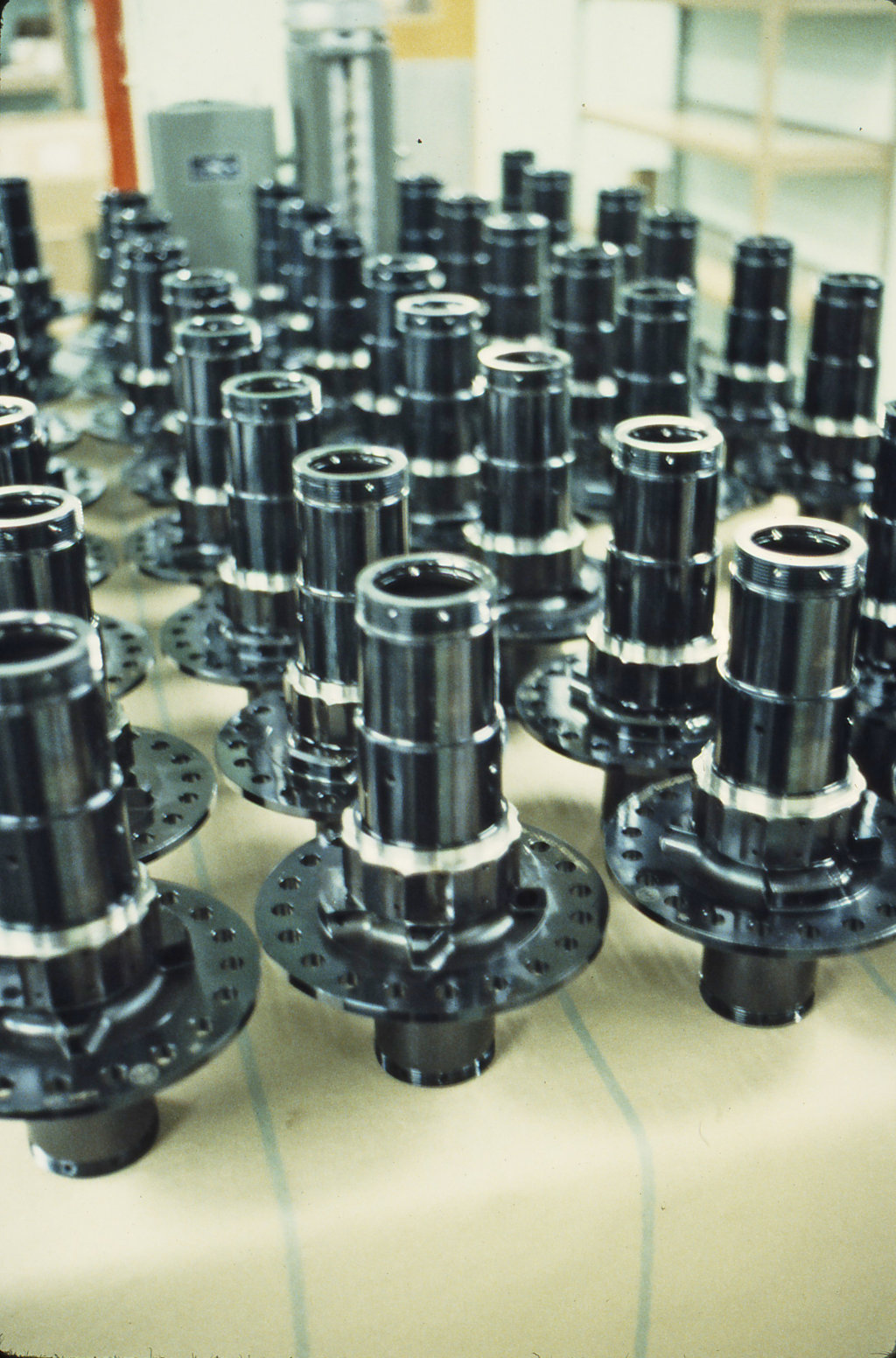

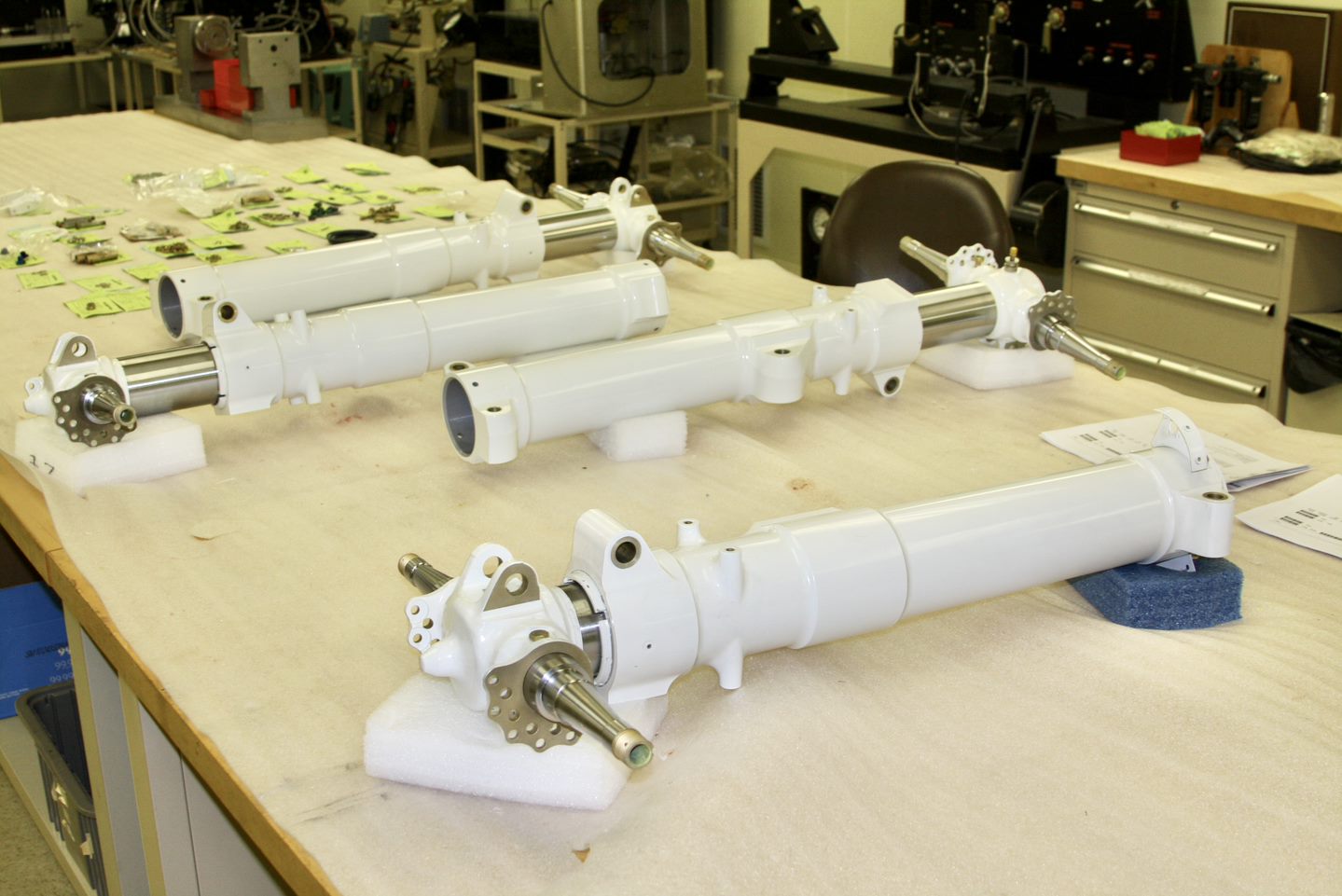

ROTARY WING PARTS MANUFACTURING

Rotorcraft Spare Parts Production Facility

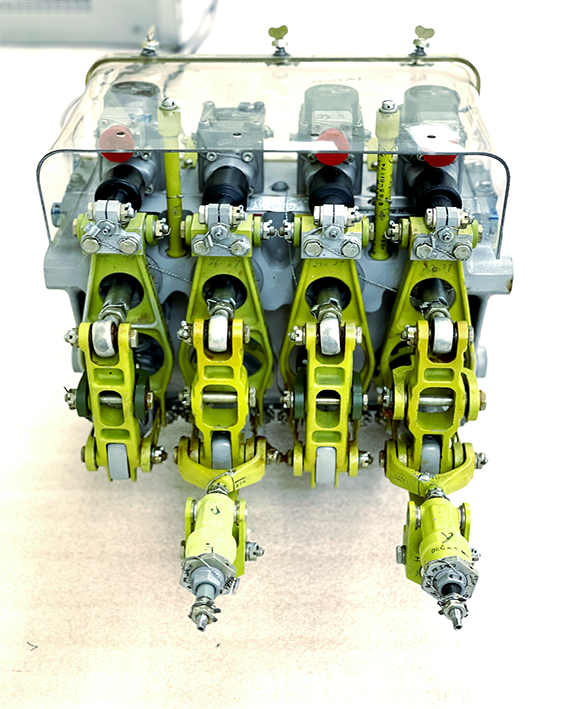

Rotair is one of the top aerospace parts manufacturers, providing thousands of various Rotary Wing Components. This encompasses a wide variety of Rotair Aerospace precision-crafted parts for the Sikorsky UH-60 Black Hawk and H-53 Series Platforms which includes mechanical flight control and flight-critical sub-assemblies, complete landing gear, hydraulic systems, and more. Rotair manufactures highly complex and critical assemblies such as the UH60 Stabilator Amplifier with over 600 components, the Main Rotor Spindle, as well as the Bifilar, which require critical machining and specialized tools and assembly techniques. Using a diverse base of highly qualified vendors and our years of experience in managing large projects, we are capable of tracking thousands of components, including Rotair manufactured parts for the Sikorsky UH 60 Black Hawk, through production to their final assembly for timely delivery of a high-quality product. Our UH 60 helicopter maintenance is second to none.

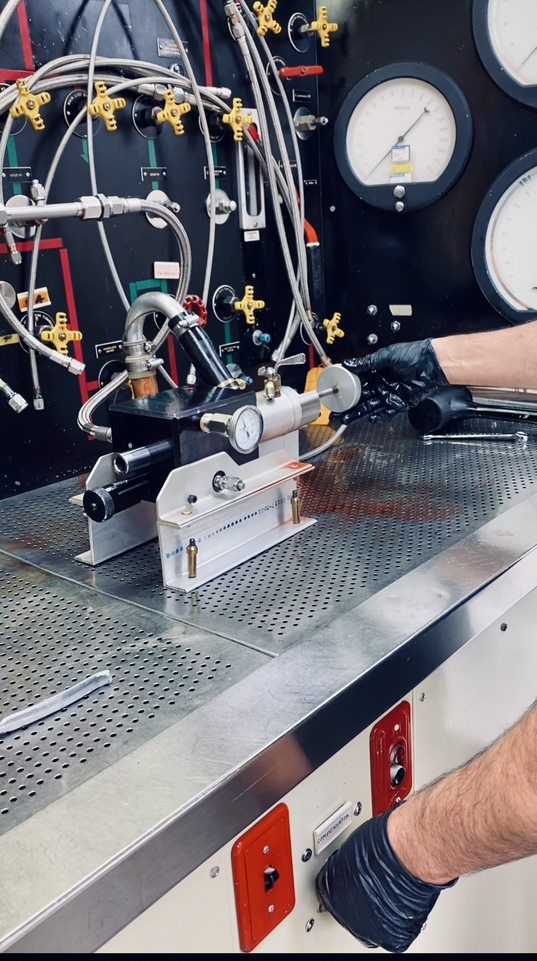

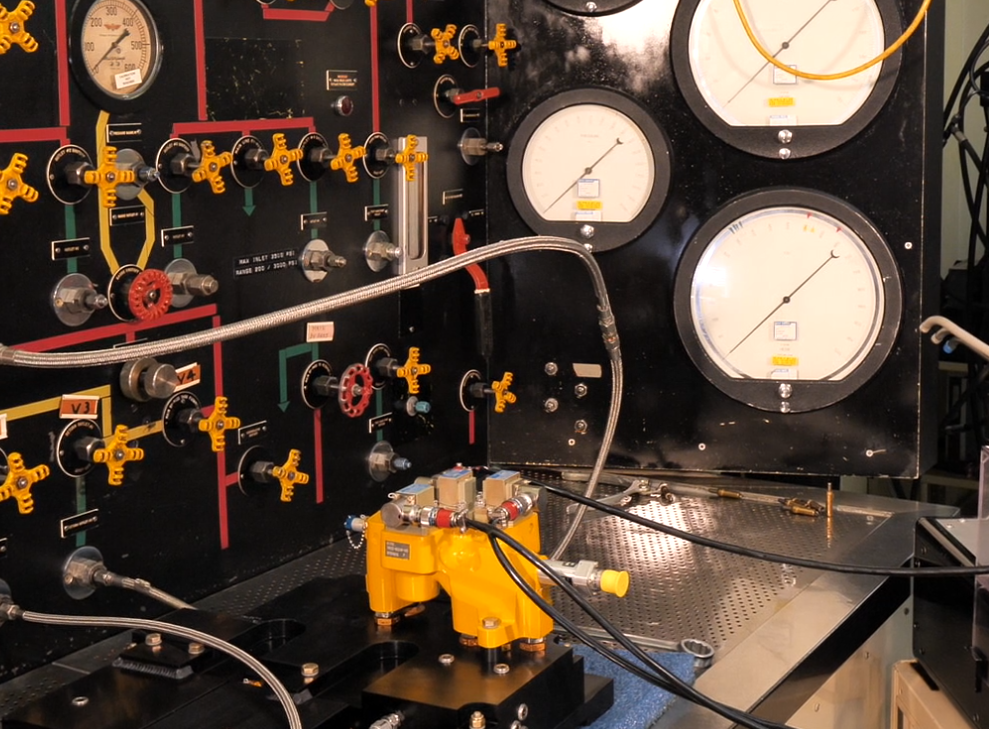

LARGE TESTING FACILITY

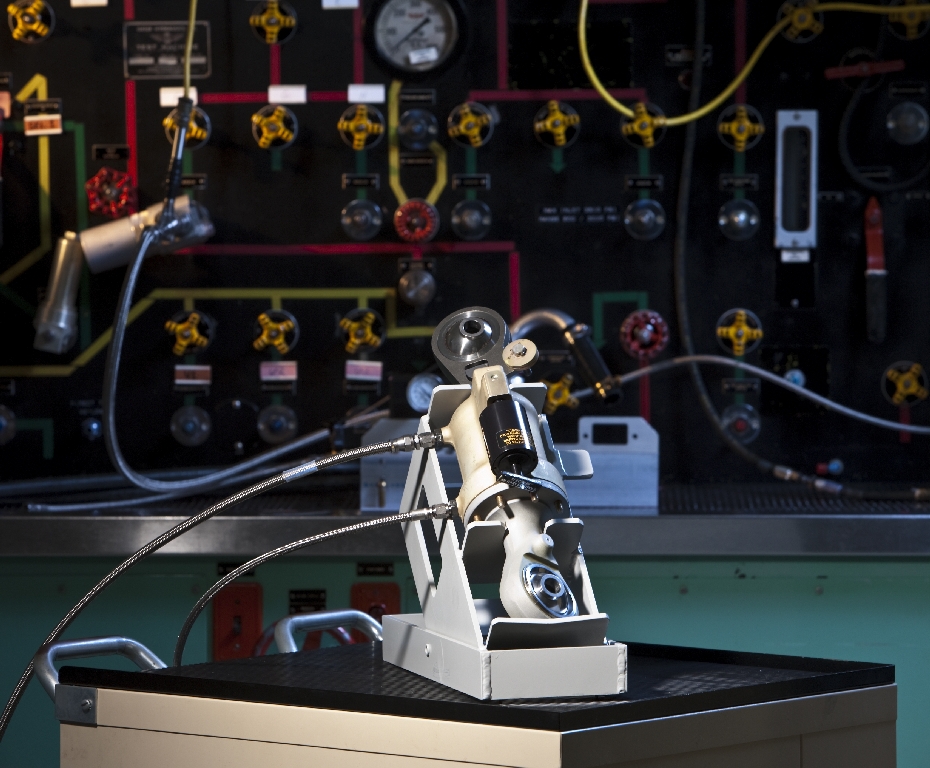

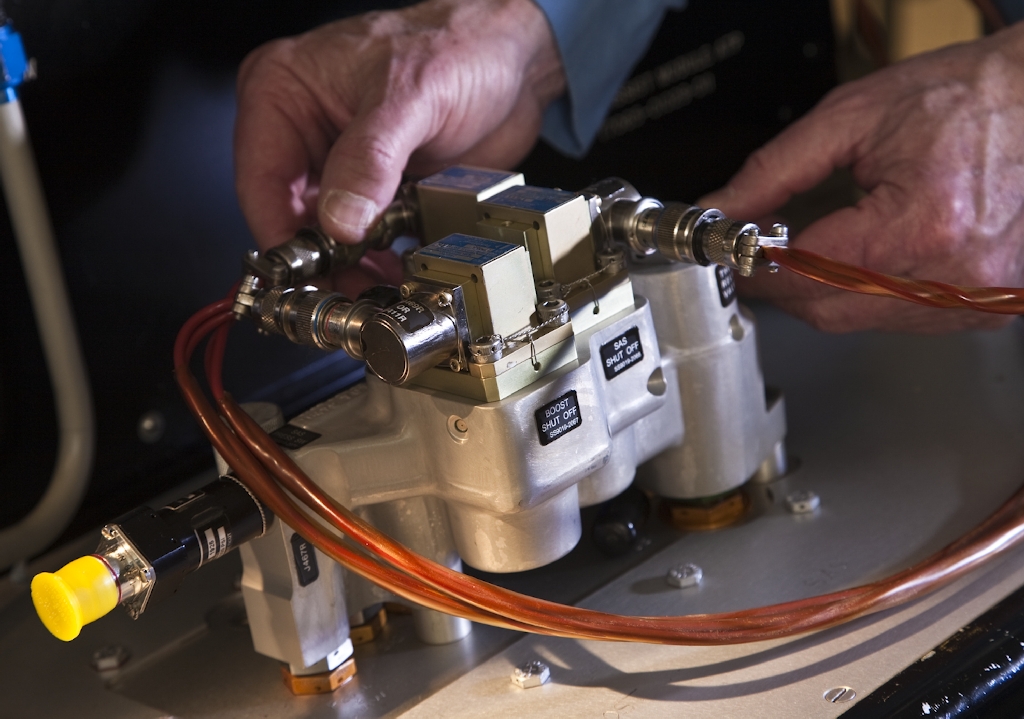

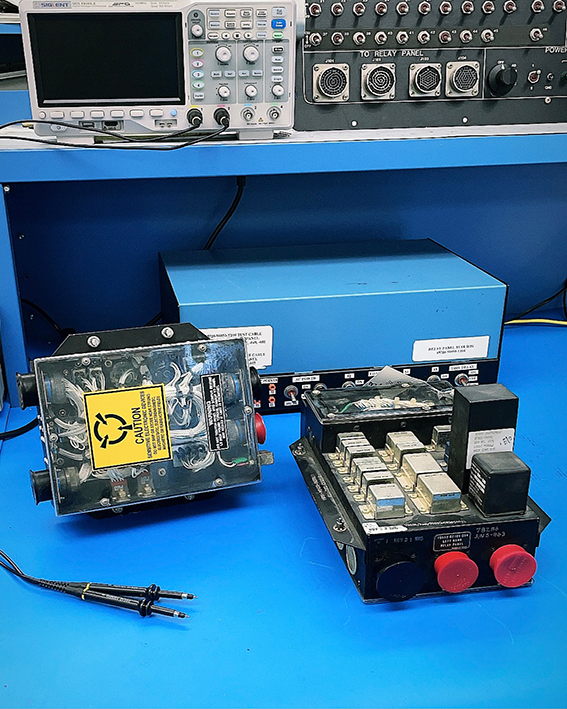

HYDRAULIC TEST FACILITIES

Rotair maintains a high-capacity hydraulic test stand housed in a Class 100,000 Clean Room meeting the requirements of FED-STD-209 and ISO 14644-1, -2. This facility is capable of testing a wide variety of hydraulic components, for example, landing gear, dampeners, servos, aircraft hydraulic control systems, and much more. Rotair has a variable drive (vari-drive) test cell capable of simulating the power output of the accessory gear box modules for several helicopters.

STATE OF THE ART

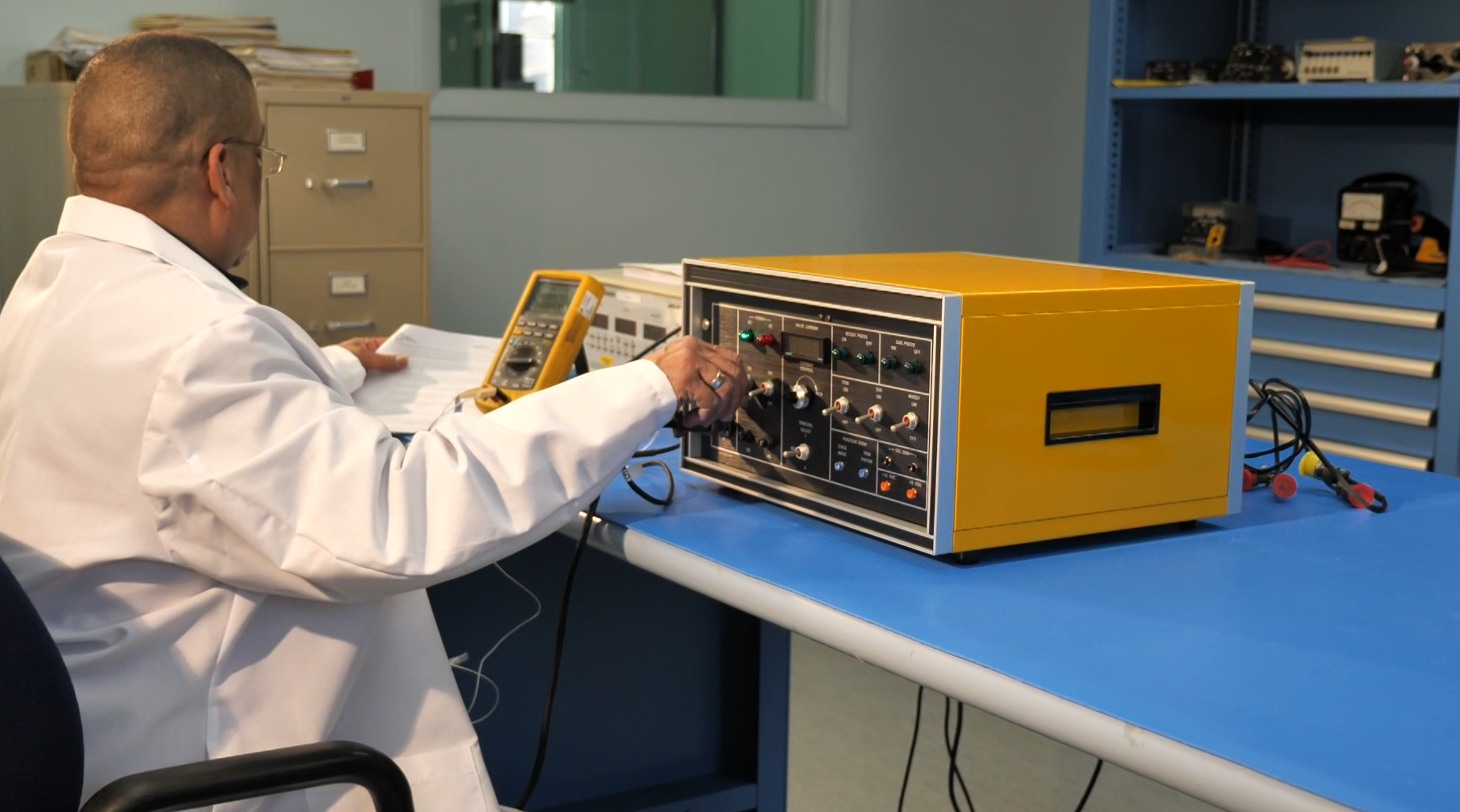

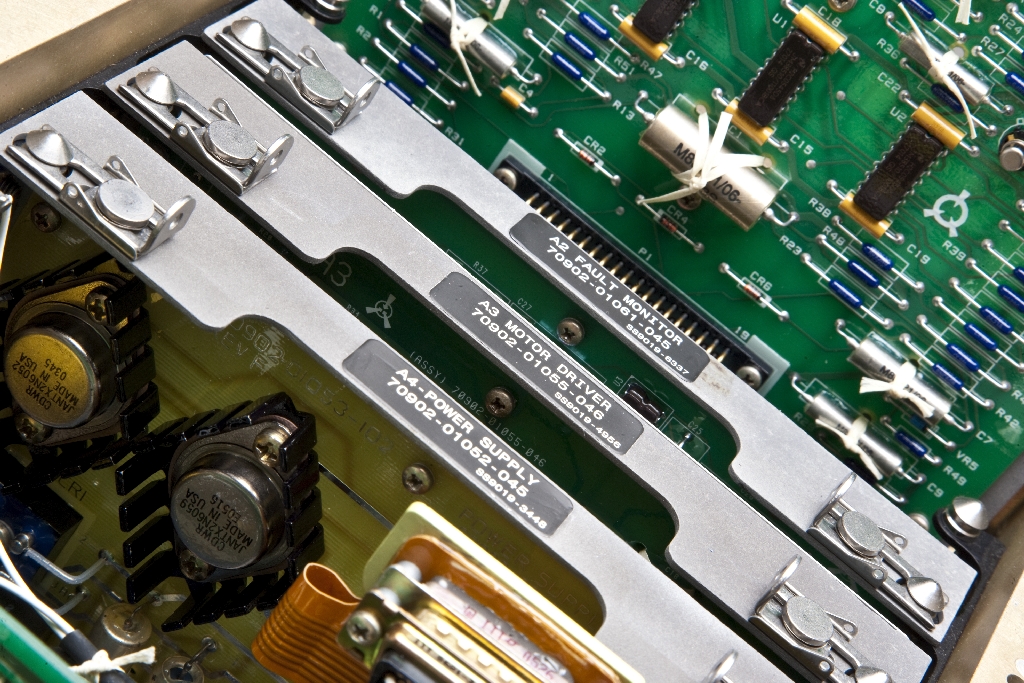

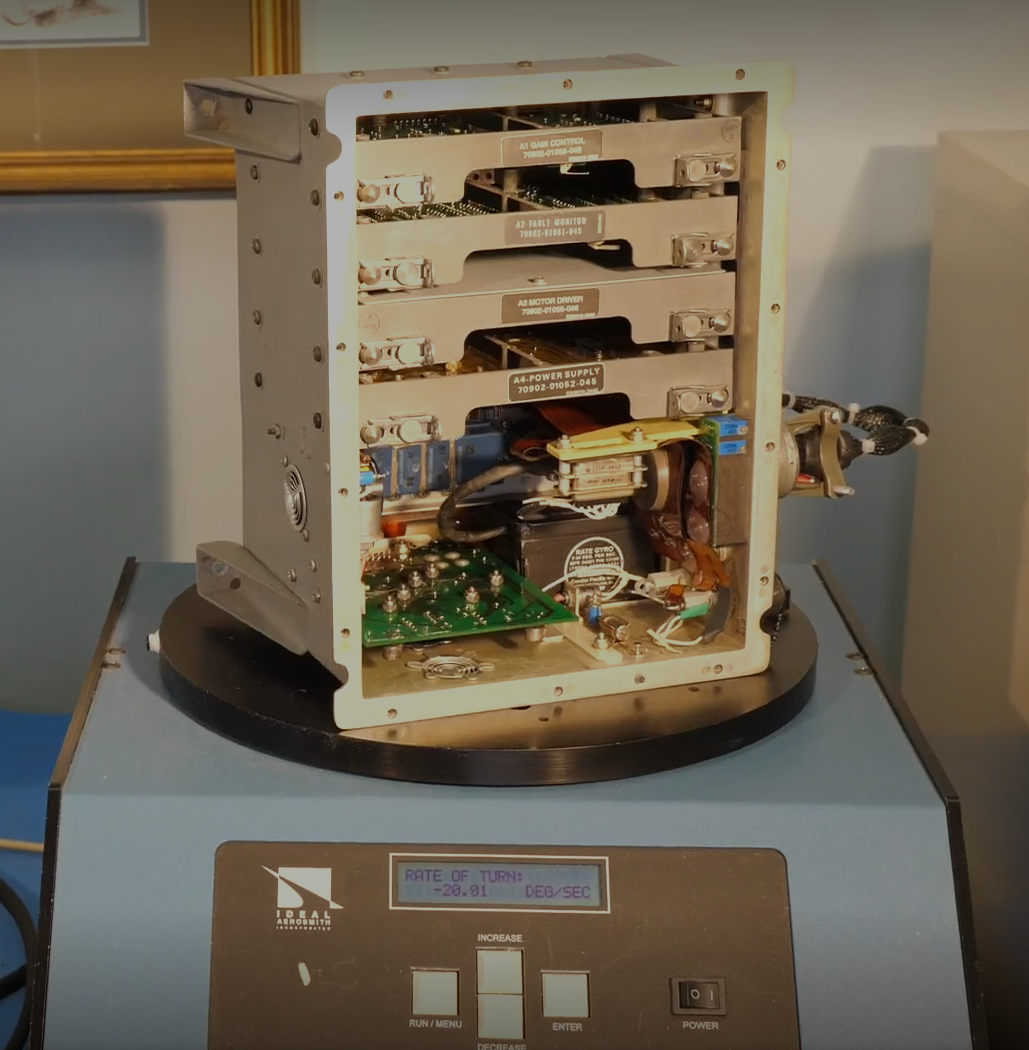

AVIONICS DEPARTMENT

Rotair manufactures highly complex and critical assemblies such as the UH60 Stabilator Amplifier with over 600 components. We manufacture and overhaul a variety of components including microprocessor-based components, flight controls electronics, power supplies, control panels, relays, and much more.

TESTING SYSTEMS

ENVIRONMENTAL & VIBRATION

Rotair operates a computer-controlled environmental chamber capable of cycling through a temperature range of -70 to +180 degrees C. Environmental testing can take place while necessary aircraft voltages, frequencies, and currents are supplied to the components under test. Rotair has an Unholtz – Dickie Vibration Platform capable of a broad spectrum of vibration frequency domains under computerized control including Random, Sine, Shock, and their various combinations by our specialized and highly trained team that meets NAVMAT P-9492 standards.

MODERN AND DURABLE

PAINT FACILITY

We have the capabilities to apply paints and other organic finishes to the most exacting aerospace standards, such as MIL-PRF-23377 and MIL-DTL-53039.

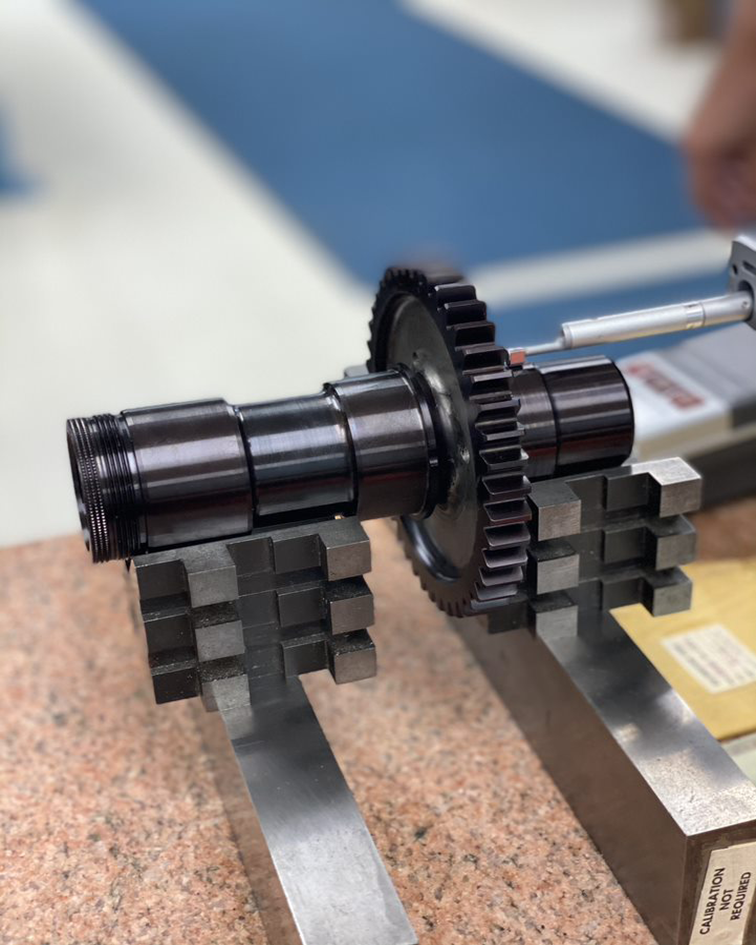

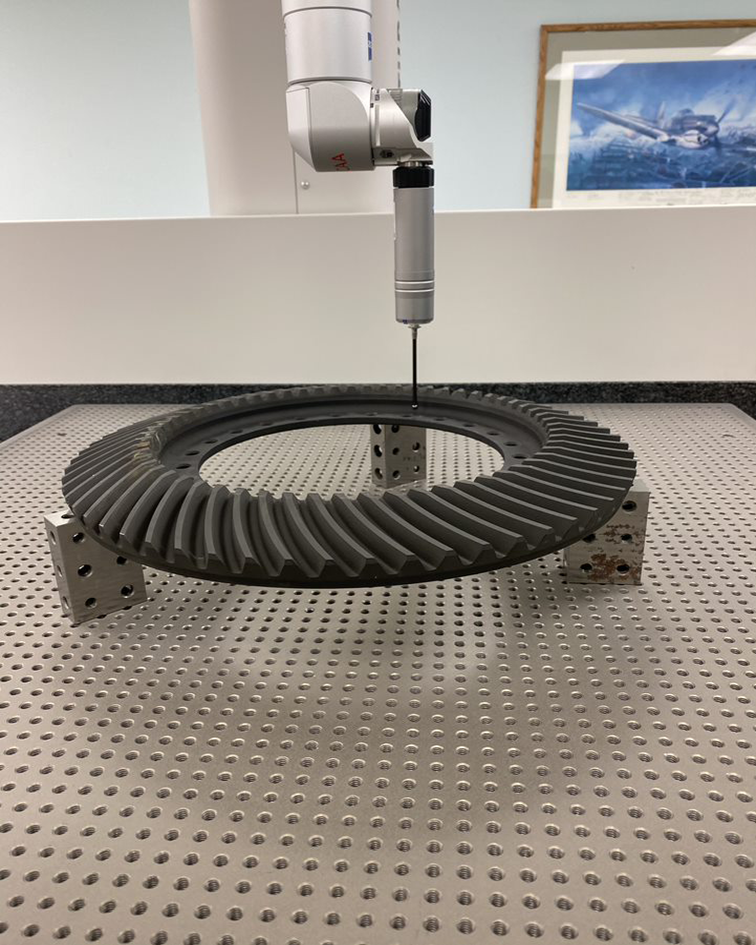

GEAR SPECIALISTS

CMM INSPECTION

SOPHISTICATED ASSEMBLIES