ROTARY WING REPLACEMENT PARTS

HELICOPTER REPLACEMENT PARTS

We manufacture spare helicopter parts used on Sikorsky S-70, Bell, Boeing and various other platforms. We offer testing, inspection, overhaul, and repair services for aircraft components, as well as selling helicopter replacement parts. We serve customers in commercial and defense aviation sectors worldwide with their helicopter spare parts needs. Rotair Aerospace Corporation was founded in 1968 and is based in Bridgeport, Connecticut. For more than four decades, the performance of Rotair Aerospace in the supply and manufacture of quality helicopter parts has made it an industry leader.

Thanks to our impressive experience in the industry, you can always be sure that you will receive the highest-quality service. We are a leading supplier of helicopter spare parts, specializing in replacement parts for Black Hawk helicopters and various other Sikorsky models, and when you get in touch with us you will quickly see why. With a wide range of capabilities and superior standards, there’s no other company to turn to. No matter what kind of needs you might have when it comes to helicopter parts, we have you covered. Give us a call today for more information.

WORLD CLASS FACILITY

Rotair is able to produce highly complex and critical assemblies at our world class production facility.

CAPABILITIES

Testing and inspection services for customers who want to ensure their components meet airworthiness criteria.

HIGHEST STANDARDS

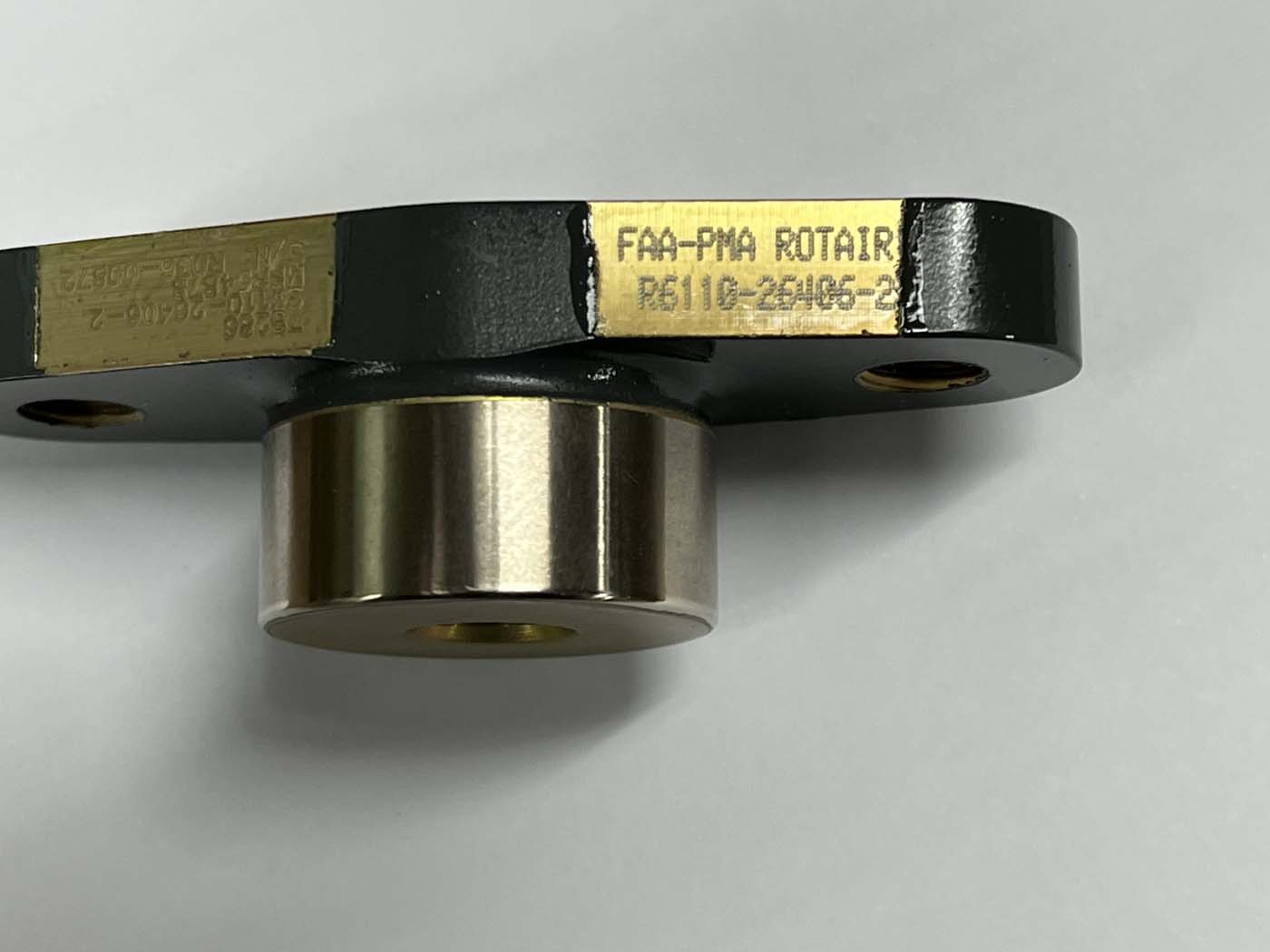

Rotair is the most comprehensive source anywhere for FAA-PMA approved parts with over 3000 PMA’s currently held.

STOCK WHEN YOU NEED IT

Rotair maintains an extensive inventory of high-use and life-limited components.

Get in touch!

OUR STORY

ABOUT ROTAIR

For more than four decades, Rotair’s performance in supplying quality helicopter replacement parts has made Rotair a leader in the industry. It is a reputation that has come about through continual striving for excellence in every area of our business. Our CEO, Wes Harrington, is committed to that excellence.

The parts you purchase from Rotair meet all the design and performance requirements of the original component. We can provide Black Hawk and S 70 helicopter parts. Testing to and frequently beyond specification is standard procedure. This helps assure that only conforming parts are shipped to our customers. Rotair’s precision extends beyond product quality into such areas as technical support, research, inventory control, record keeping, and packaging and shipping. Around the world, Rotair is your top source for a wide range of helicopter components, including those for Sikorsky and selected Bell helicopter models. We are prepared to prove that we offer you levels of precision, availability, and service unsurpassed by any other source.

ROTAIR AEROSPACE CORPORATION – A LEADER IN THE DESIGN, MANUFACTURE, ASSEMBLY AND SALE OF HELICOPTER REPLACEMENT PARTS FOR ROTARY WING AIRCRAFT.

CONTACT US FOR ALL YOUR ROTARY WING COMPONENTS

More Than Just a Supplier

In addition to our helicopter parts supply, we provide testing, inspection, overhaul, and repair services for aircraft components. Our team is composed of experts in the field committed to delivering the best service possible. We serve customers in commercial and defense aviation sectors worldwide, ensuring their helicopter spare parts needs are met.

OUR TRUSTED AND PROFESSIONAL

FACILITIES AND CAPABILITIES

In addition to providing top quality parts for rotary wing aircraft, Rotair also provides testing and inspection services for customers who want to ensure their components can meet airworthiness criteria. Got a backlog for application of organic finishes? Rotair has years of experience and can return your parts to your exact finish specifications.

PRODUCTION FACILITY

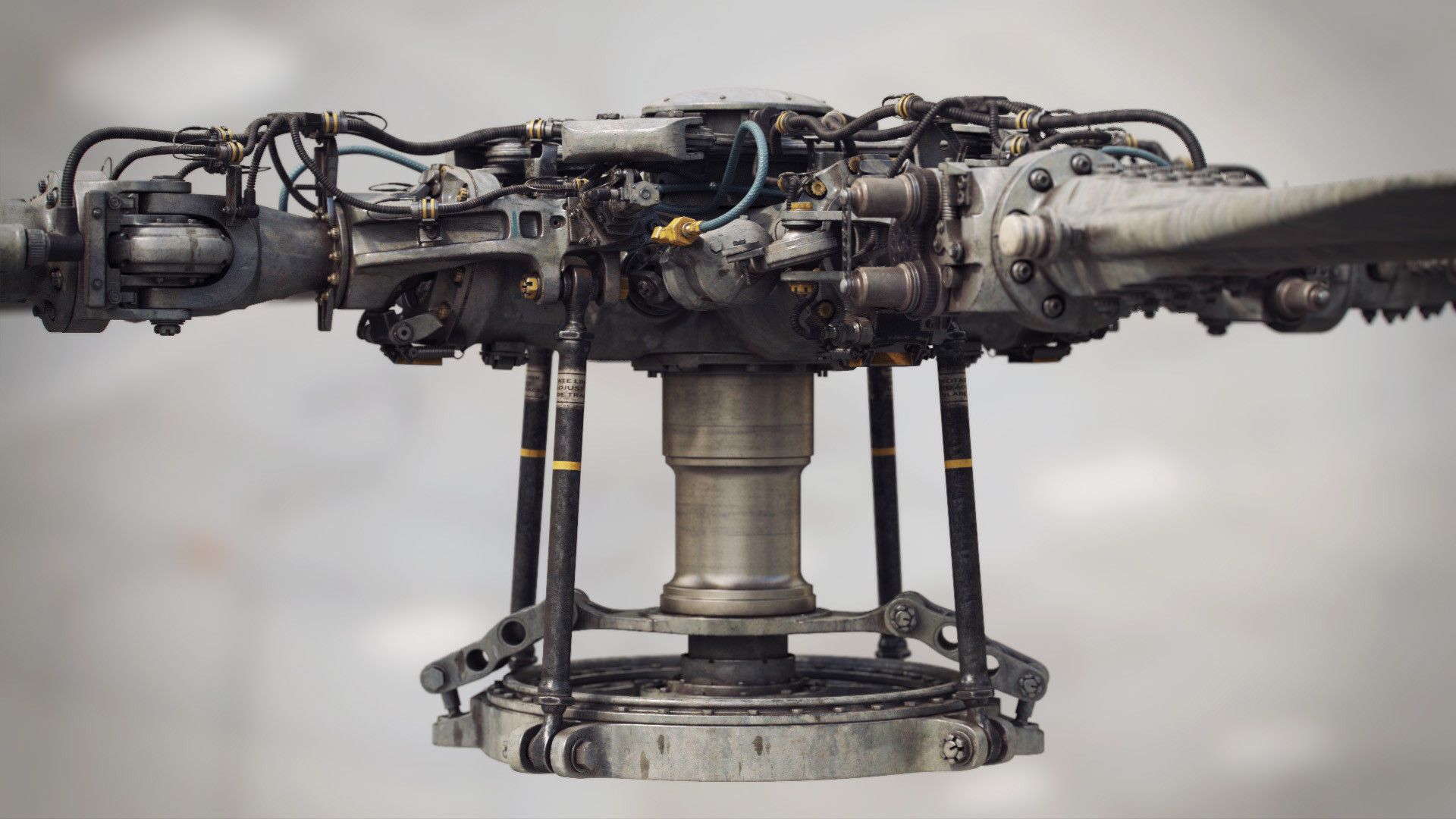

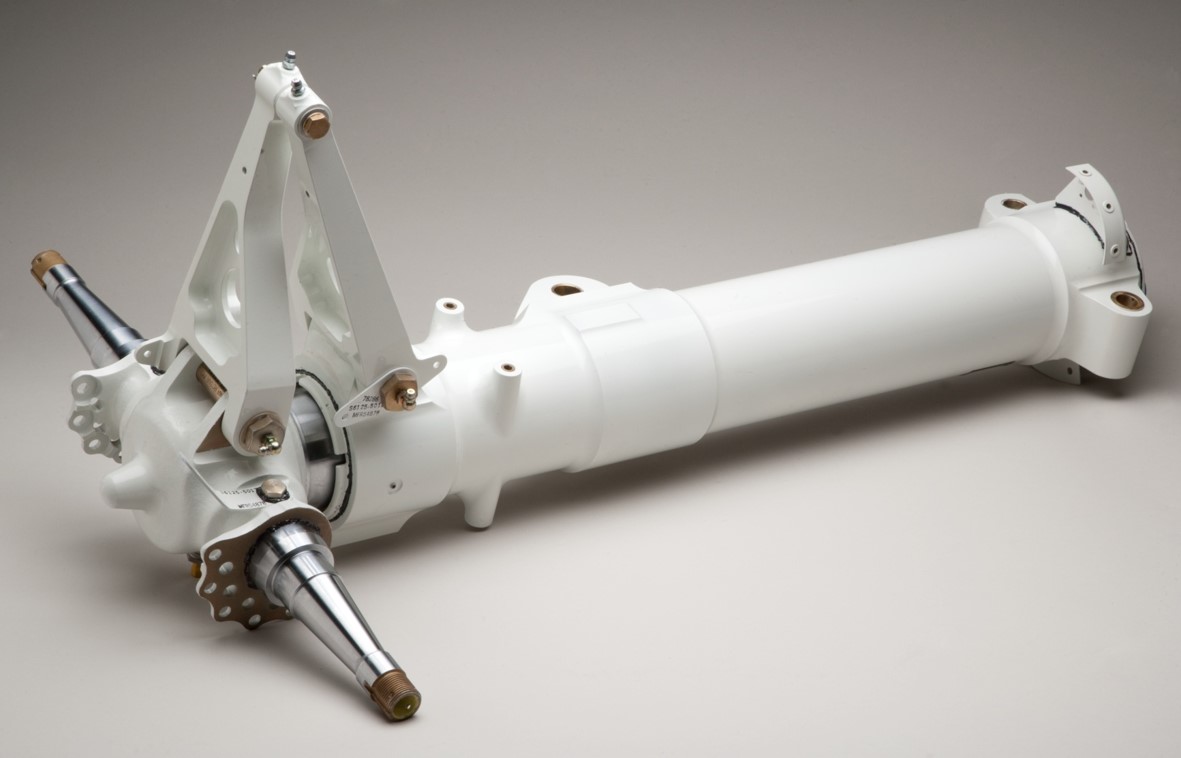

Rotair manufactures highly complex and critical assemblies such as the UH60 Stabilator Amplifier with over 600 components; the Main Rotor Spindle…

HYDRAULIC TEST FACILITY

Rotair maintains a high-capacity hydraulic test stand housed in a Class 100,000 Clean Room meeting the requirements of FED-STD-209 and ISO 14644-1, -2…

AVIONICS

Rotair has a state-of-the-art avionics facility meeting requirements of MIL-STD-1695 and includes conductive flooring and benches with separate ESD…

COMPLETE SOLUTIONS

Parts Manufacturing Approval

The fundamental expertise of Rotair Aerospace Corporation is delivering FAA-PMA replacement components for rotary wing aircraft. The FAA Design Approval standards and policies are strictly followed during our PMA process. Our products meet or exceed OEM design specifications while complying with regulatory body requirements. Our engineers collaborate with customers to guarantee that the final product satisfies all requirements, including shape, fit, function, and flight safety.

Your Helicopter Spare Parts Supplier

Rotair Aerospace offers high-quality replacement parts for a variety of helicopter platforms, including military models such as the UH-60 Black Hawk and commercial helicopter parts, like the S-70 helicopter parts. We also offer UH-60 replacement parts and UH-60 spare parts for UH-60 helicopter maintenance tasks.

MILITARY HELICOPTERS

Rotair is currently meeting government demands for quality military helicopter parts through several major contracts in support of the Army’s UH-60 Black Hawk. Additionally, Rotair satisfies hundreds of Defense Logistics Agency (DLA) requests annually.

COMMERCIAL HELICOPTERS

Rotair is committed to meeting our customers’ needs including special priority to minimize AOG downtime. This is accomplished by maintaining an extensive inventory of high-use and life-limited components for our commercial customers.

OUR SUPPLIERS

We are very proud to work with some of the very finest craftsmen in the aerospace community. Their workmanship is reflected in the quality of every part we manufacture, assemble and sell. Learn more by clicking on the button below

STAY UPDATED AND INFORMED

OUR NEWS AND ARTICLES

How to Choose A Helicopter Repair Facility

Choosing the right helicopter repair facility is important for maintaining the safety and performance of your aircraft. Whether you own a helicopter or manage a fleet, you must ensure competent professionals handle maintenance and repairs. Here’s a comprehensive guide...

A Guide on Rotable Parts on Sikorsky Helicopters

Your Sikorsky helicopter’s rotable parts require regular maintenance. Today, we will take a closer look at what rotable parts are, how frequently they need to be taken care of, and what the different stages of servicing for rotable parts are. What Are Rotable Parts?...

The Role of Helicopter Parts in Ensuring Flight Safety

Black Hawks have many parts that work together to ensure a safe flight during every mission. Today we will explore helicopter parts that comprise a helicopter’s hydraulic system. Our hydraulic engineers subject replacement hydraulic systems to rigorous hydraulic tests...

Find the Parts You Need

If you need assistance sourcing helicopter spare parts, get in touch and we can help with your helicopter projects. Our company was founded in 1968 and is based in Bridgeport, Connecticut. With over 40 years of experience in the industry, we have established ourselves as an industry leader in the supply and manufacture of quality helicopter parts, including Black Hawk UH-60 helicopter parts.

We are a leading supplier of replacement helicopter parts, specializing in components for the Black Hawk UH-60, CH-53, AH-64, and other Sikorsky and Boeing models. Our superior standards and various capabilities ensure we deliver the highest-quality service. Our helicopter replacement parts service is managed by Wes Harrington, who has extensive experience in the industry.

If you’re looking for Rotair Manufactured Parts for the Sikorsky UH-60 Black Hawk for sale, Black Hawk parts, or other helicopter spare parts, we have you covered. Contact us today to learn more about our helicopter replacement parts service.